2025-07-11

Electric Alternative for Heavy-Duty Water Tech

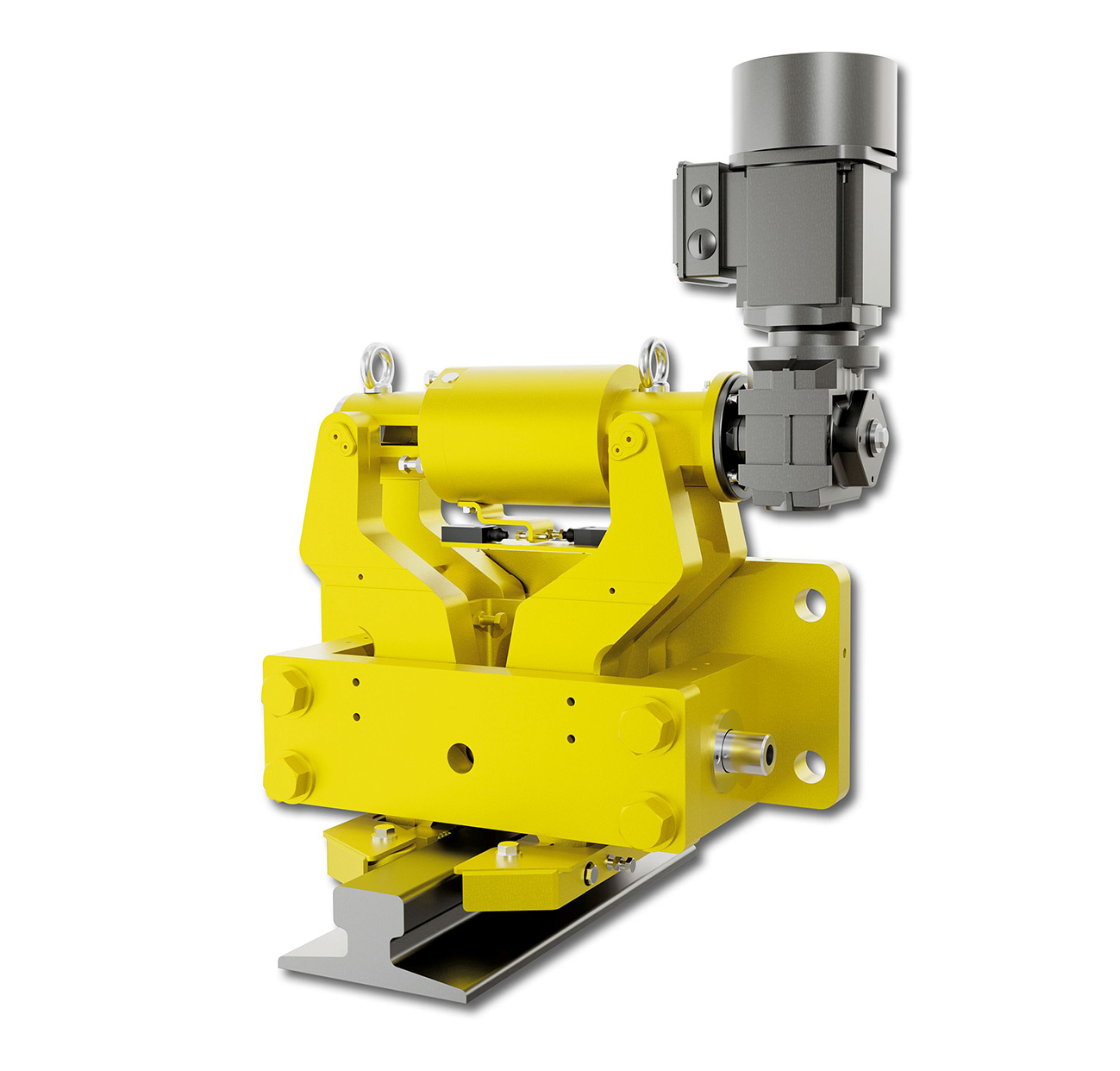

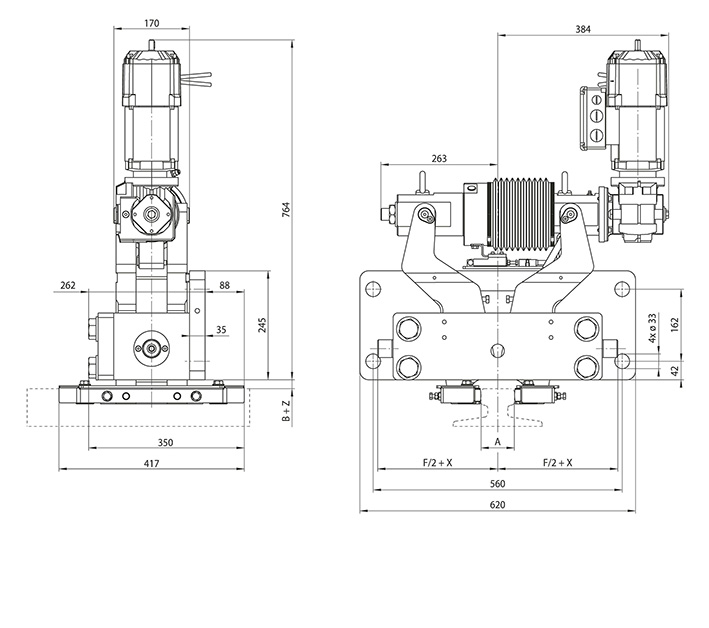

RINGSPANN expands its brake portfolio with new heavy-duty rail clamps

Hydraulic heavy-duty brakes have been part of the RINGSPANN portfolio for a long time. Now, however, the company is presenting a real novelty: DR085 FEK 200 spring-operated and electrically opening rail clamps. Manufacturers of port and container cranes in particular, as well as conveying, handling and shipyard facilities for use in areas close to water and offshore are thus offered a brake technology alternative for the implementation of environmentally friendly drive systems. Since the design of the new storm brake is similar to its hydraulic sister models, it is also suitable for modernisation and retrofitting.

Bad Homburg, July 2025. – „In many port, dock and shipyard facilities around the globe, rail brakes and rail clamps from RINGSPANN make their contribution to safety to ensure that cranes and conveyor systems operating here cannot start up unchecked during strong storms. However, while manufacturers of these heavy-duty systems, which are mostly used near water or offshore, as well as plant manufacturers in the steel industry, used hydraulic brakes for storm protection almost without exception for decades, today they are increasingly looking for environmentally friendly alternatives that can be operated without the latent risk of oil leakage. "We recognised this need early on and worked intensively on the development of rail clamps for heavy-duty applications in maritime environments that can be closed mechanically – i.e. by spring force – and released electrically. This work was successfully completed with the delivery of our new DR085 FEK 200 to the first customers about a year ago. We recently presented this innovation in the field of storm brakes for the first time to a large audience at the container handling trade fair TOC Europe 2025 in Rotterdam," reports Martin Ohler, Business Developer Brakes at RINGSPANN. In the meantime, it has become clear that the new electromechanical DR085 FEK 200 is attracting growing interest not only from manufacturers of rail-guided port, dock and shipyard equipment, but also from designers of drive systems for tower cranes, bucket wheel excavators, steel mill cranes and power plants.

Intelligent design

Heavy-duty rail clamps, which close and open electrically by spring force, have so far been a rarity in the storm brake market. Their development requires a good deal of experience and know-how, and their design is particularly challenging. However, RINGSPANN engineers have mastered this task with flying colours, because, as Martin Ohler emphasises, "all DR085 FEK 200s delivered to date are working to the complete satisfaction of the customers". Since the company's brake experts also based the design of the new rail clamps on the design of the hydraulic sister models and made a number of components – such as levers and frames – identical, this also offers maintenance technicians, modernisers and retrofitting specialists an innovative replacement component. Wherever the threat to groundwater, coastal or inland waters calls the use of hydraulic systems into question, the oil-free DR085 FEK 200 from RINGSPANN should prove to be a welcome solution to the problem. In addition, these rail clamps can be used not only as storm protection, but also as a holding, positioning and parking brake for rail-guided crane, container, bulk material or conveyor systems during loading and unloading.

Space-saving design

RINGSPANN currently offers its new electromechanical storm brake with holding forces of up to 200 kN. As with its spring-operated and hydraulically released rail brakes and rail clamps, the company’s technicians have also achieved a very advantageous force-to-size ratio in the DR085 FEK 200, resulting in a space-saving design. "This gives the designers of the drive and safety systems a lot of leeway in the concrete design of the installation or mounting situation," states Martin Ohler.

Storm and holding brakes from RINGSPANN have proven their worth for decades in ports, shipyards, mining facilities, as well as in steel and power plants, as a contribution to the realisation of high safety standards. There are probably only a few manufacturers who can boast comparable expertise in the field of industrial brakes for heavy-duty applications. Especially since the company ensures a high level of availability of its industrial brakes by keeping all technically relevant components available at its European locations. A large proportion of spare and wear parts are available on demand, and it is also possible to integrate brake assembly into just-in-time scenarios. Last but not least, RINGSPANN offers its customers a high degree of planning and investment security on the basis of the extensive range of products offered by its one-stop shop and its in-house test bench technology. ar

All major industrial brake types

Industrial brakes from RINGSPANN serve as stopping, controlling and holding systems in crane and conveyor systems, handling and lifting systems, construction and mining machinery, as well as in marine, port, recycling and metallurgical technology. In its one-stop shop, the company offers its customers an almost complete range of brakes that covers all important types of construction and functions. To make it easier for engineers and designers to select the optimal brake, RINGSPANN also provides a free calculation tool on www.ringspann.de. It allows the determination of braking torques and braking forces. Among other things, it can be used to calculate: the braking of rotating masses, on vertical and horizontal rails, as well as of winches, conveyor belts, landing gears, wind turbines and via the drive power. The tool also records the holding and controlling of coiling processes.